What material is wood plastic flooring

Wood plastic flooring is a high-tech green and environmentally friendly material made by mixing wood (wood cellulose, plant cellulose) as the base material with thermoplastic polymer materials (plastics) and processing aids. This material combines the properties and characteristics of wood and plastic, and is a new type of environmentally friendly high-tech material, abbreviated as WPC (Wood Plastic Composites) in English.

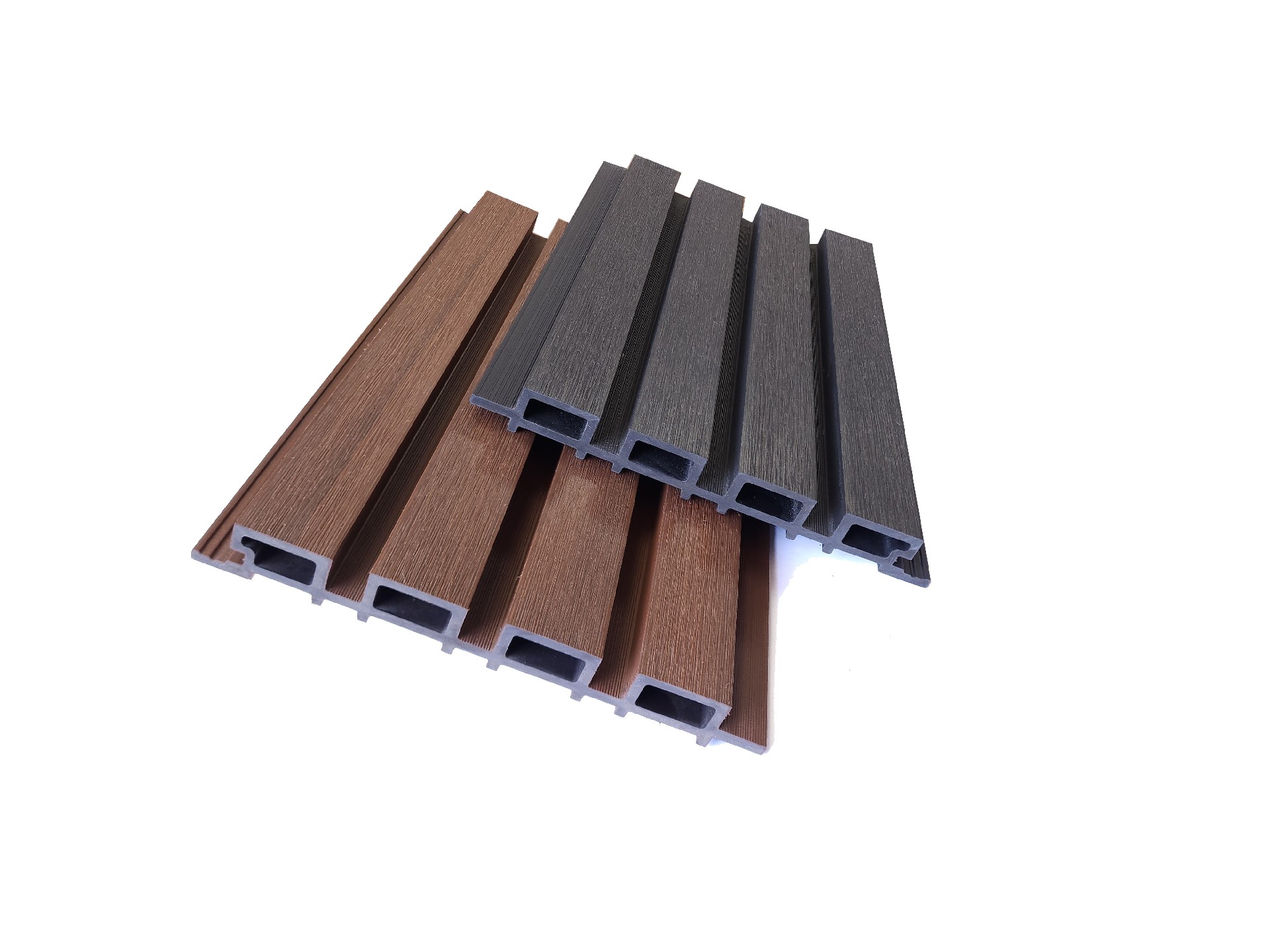

The main components of wood plastic flooring include PE (polyethylene), wood powder or bamboo powder, as well as lignin and recycled plastics produced during the production of high-density fiberboard. These materials are processed into wood plastic composite materials through granulation equipment, and then made into flooring through extrusion molding technology. This type of flooring not only has the processing characteristics of wood, which can be sawed, drilled, and nailed using ordinary tools, but also has the water and anti-corrosion properties of plastic, making it suitable for outdoor environments.

The advantages of wood plastic flooring include waterproofing, moisture resistance, insect resistance, termite resistance, fire resistance, etc., which can effectively extend the service life. In addition, it also has high environmental friendliness, does not contain benzene substances, has low formaldehyde content, can be recycled, and conforms to the national policy of sustainable development. Wood plastic flooring comes in a variety of colors and textures, which can be chosen according to personal preferences. Its high fire resistance also allows it to self extinguish when exposed to fire, without producing toxic gases.